China Thermal Transfer Labels vs Direct Thermal: ODM Manufacturers & Suppliers

When considering thermal labels for your business, understanding the difference between China thermal transfer labels and direct thermal options is crucial. We specialize in providing high-quality labels that meet diverse needs. As an exporter and manufacturer in the industry, we appreciate the importance of selecting the right label type for your applications, China thermal transfer labels offer durability and vibrant colors, ideal for long-lasting labeling needs. On the other hand, direct thermal labels are perfect for short-term usage, offering immediate printing without the need for ribbons, At ShenZhen Sailing Paper Co., Ltd., we pride ourselves on delivering exceptional products tailored to your specifications. Whether you're looking for bulk orders or specific sizes, our experienced team is here to assist you. Trust us to provide solutions that enhance your business operations and improve efficiency. Let’s explore what works best for you together!

Avoiding Pitfalls China Thermal Transfer Labels Vs Direct Thermal Service Factory

When it comes to selecting the right labeling solution for your products, understanding the differences between thermal transfer labels and direct thermal labels is crucial for global procurement. At Sailing, a company that has transformed from a local paper converter to an international leader in the printing and packaging sector since our establishment in 2011, we are committed to providing quality insights into these labeling technologies.

Thermal transfer labels utilize a ribbon to transfer ink onto the label substrate, making them highly durable and resistant to various environmental factors. This means they are ideal for applications requiring longevity, such as outdoor products or items exposed to moisture and abrasives. In contrast, direct thermal labels rely on heat-sensitive material that turns black when heated. While they're often a more cost-effective option for short-term use, they may fade over time—making them less suitable for long-term product labeling.

Selecting the right labeling method can significantly affect your supply chain efficiency and branding. At Sailing, with production capabilities in both China and Malaysia, we ensure that our global clients have access to a diverse range of labels tailored to meet their specific needs. As you navigate these options, consider the intended use, environmental conditions, and the longevity of your labels to avoid common pitfalls. Trust our expertise to help elevate your business with the right labeling solutions.

Avoiding Pitfalls: China Thermal Transfer Labels Vs Direct Thermal Service Factory

| Feature | Thermal Transfer Labels | Direct Thermal Labels |

|---|---|---|

| Print Quality | High density, better for detailed graphics | Good for simple text and barcodes |

| Durability | Water, heat, and chemical resistant | Less durable, can fade with exposure |

| Cost | Generally more expensive due to ribbon cost | Lower cost, no ribbon required |

| Print Speed | Slower, due to ribbon changes | Faster printing capabilities |

| Printer Compatibility | Requires dedicated thermal transfer printer | Compatible with most direct thermal printers |

| Applications | Ideal for high-quality labels and tags | Best for short-term use and non-durable applications |

| Environmental Resistance | Better resistance to environmental stress | Limited environmental durability |

Champions of China Thermal Transfer Labels Vs Direct Thermal Stands Out More Than a Supplier - A Partner

D

David Wilson

High-quality materials and excellent performance. The customer support team was highly professional and responsive.

08

June

2025

D

Daniel Martinez

The product quality is outstanding. Their team’s expertise makes the entire experience smooth and efficient.

22

June

2025

E

Ethan Hernandez

I highly recommend this product! The after-sales support exceeded my expectations.

18

June

2025

N

Nathaniel Rivera

Outstanding quality! Their expert support team made the experience delightful.

27

May

2025

H

Henry Adams

Exceptional quality! Their team responded promptly to my inquiries, showcasing great professionalism.

23

June

2025

C

Chloe Young

Wonderful quality! The knowledge of their support staff really helped me with my purchase.

27

June

2025

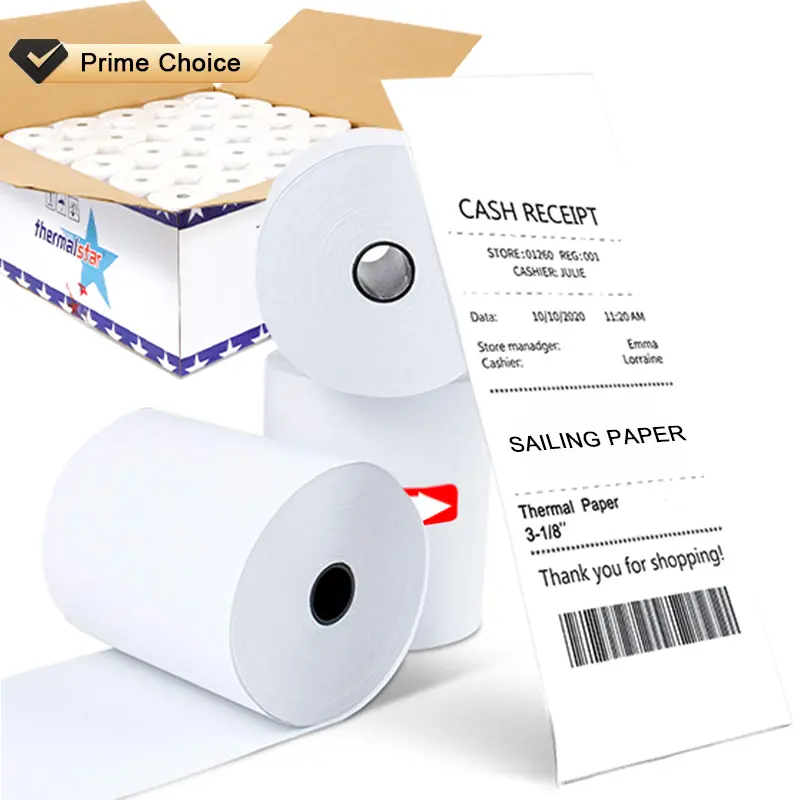

Thermal labels

Thermal labels