OEM Direct Thermal Labels: Wholesale Products & Quotes Available

When it comes to printing, I am excited to share that our OEM direct thermal labels are a game changer! Perfect for businesses needing high-quality, reliable labeling solutions, these products are designed to perform efficiently in various applications. I’ve found that the best feature is their compatibility with most thermal printers, making them easy to use without any fuss, As a trusted exporter in the industry, we offer a diverse range and custom sizes to meet your specific requirements. With ShenZhen Sailing Paper Co., Ltd., you can expect consistent quality and durability in every label. Our direct thermal labels not only save you time but also enhance your packaging and shipping processes, If you’re looking for products that make your work easier and more efficient, I highly recommend checking us out. Let’s elevate your labeling needs together with our outstanding solutions!

Tips & Tricks for OEM Can You Write On Direct Thermal Labels Company Your Trusted OEM Partner Your End-to-End Solution

In the ever-evolving landscape of industrial demands, choosing the right partner for your OEM needs is crucial. At Sailing, we understand the complexities faced by global buyers when sourcing direct thermal labels. With over a decade of experience, our commitment to quality and reliability has positioned us as a trusted OEM partner. Our operations in China and Malaysia enable us to streamline production and export, ensuring your labels meet international standards.

When working with direct thermal labels, it’s essential to consider factors such as material compatibility, printer performance, and environmental conditions. Our team of experts is dedicated to providing tailored solutions that enhance your operational efficiency. We leverage advanced technology and industry insights to deliver end-to-end solutions, from initial design to final delivery, ensuring your labeling processes are seamless and cost-effective.

By collaborating with Sailing, you gain access to a comprehensive range of printing, packaging, and logistic consumables, crafted to meet the specific needs of your business. Together, we can navigate the challenges of global sourcing, ensuring you have the quality products needed for success in today’s competitive market. Trust us to be your partner in elevating your brand with outstanding direct thermal labels.

Tips & Tricks for OEM: Your Trusted OEM Partner for Direct Thermal Labels

| Tip/Trick | Description | Application | Benefits |

|---|---|---|---|

| Choose the Right Material | Select the appropriate label material for your application environment. | Warehouse, shipping, or retail applications. | Increased durability and print quality. |

| Optimize Print Settings | Adjust printer settings such as speed and darkness for optimal results. | Use for multiple types of thermal printers. | Improved print clarity and reduced label waste. |

| Regular Maintenance | Perform routine cleaning and maintenance on printers to ensure longevity. | Applicable to all direct thermal printers. | Prevents printing issues and extends equipment life. |

| Store Labels Properly | Keep labels in a cool, dry place to prevent damage and fading. | For all direct thermal label storage. | Ensures label integrity and usability over time. |

| Test Before Full Production | Perform test prints to ensure quality before large runs. | Any production batch of labels. | Saves time and resources by avoiding major production errors. |

Effective Ways To OEM Can You Write On Direct Thermal Labels Company Outperforms the Competition Products

A

Alexander Perez

Top quality product! The customer service staff was engaged and incredibly helpful.

13

June

2025

L

Layla Martinez

Exceptional product quality! Their support staff was warm and very professional in their approach.

04

June

2025

M

Madison Hughes

Very satisfied! The product quality and customer service exceeded my expectations.

15

June

2025

S

Samuel Reed

Amazing purchase! The product quality is true to description, and the service was professional and helpful.

13

June

2025

E

Elijah Anderson

Amazing product quality! Their service team went above and beyond to assist me.

13

May

2025

J

Jackson Wilson

Superior quality! The support team was very helpful and knowledgeable throughout the process.

05

July

2025

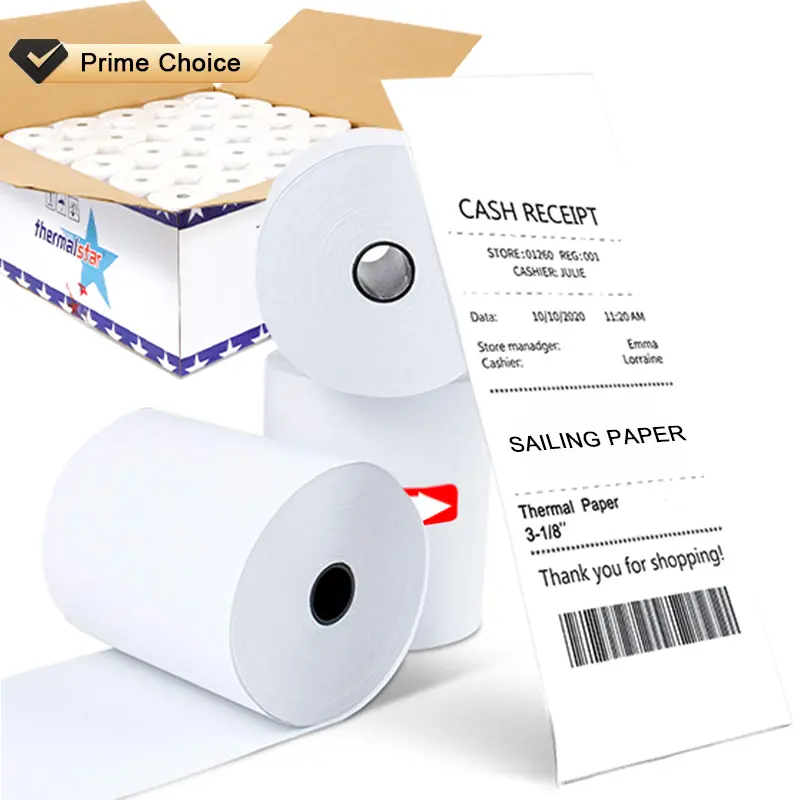

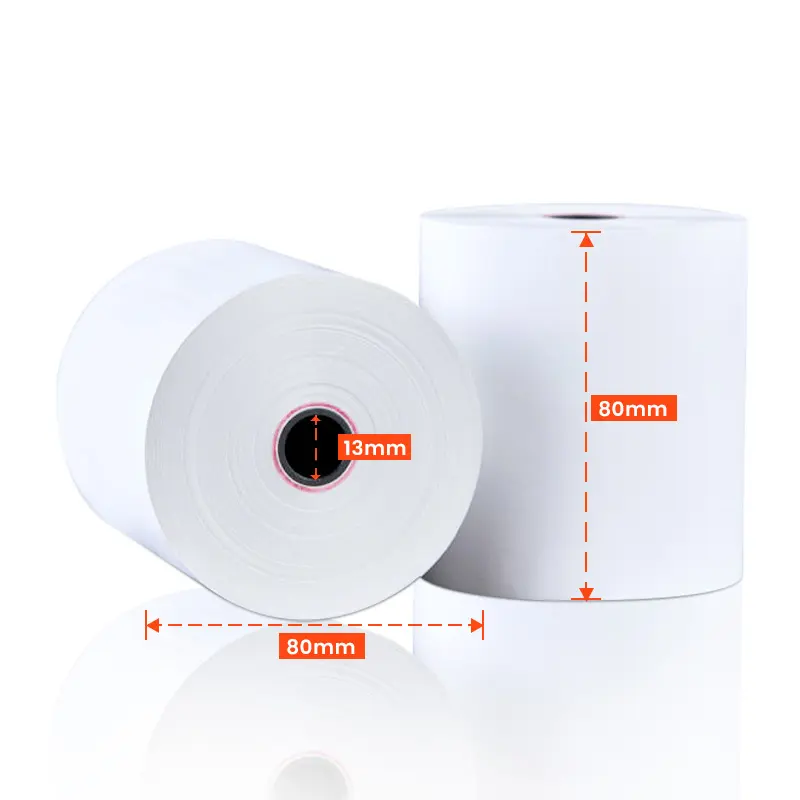

Thermal labels

Thermal labels