Thermal Transfer vs Direct Thermal Labels: Top China Supplier Products

When it comes to labeling solutions, choosing between Thermal Transfer Labels and Direct Thermal Labels can be challenging. I understand that as a buyer, you’re looking for quality products that meet CE Certification standards. At ShenZhen Sailing Paper Co., Ltd., we offer a range of high-quality labeling products designed to meet diverse industry needs, Our Thermal Transfer Labels provide durability and resistance to fading, perfect for products that require longevity, while our Direct Thermal Labels are more cost-effective and ideal for short-term applications. I can assure you that both have their place in your labeling strategy, depending on your specific requirements, Whether you need labels for inventory management, shipping, or retail, our products come with the assurance of quality and compliance, making us a trusted choice. Let’s make your labeling process smoother and more efficient with our expertly crafted solutions tailored for your business needs. Reach out today to learn more about our offerings!

How To Identify Thermal Transfer Labels Vs Direct Thermal Labels Products Stands Out Global Reach

When it comes to labeling solutions for your business, understanding the differences between thermal transfer labels and direct thermal labels is crucial for making informed purchasing decisions. At Sailing, an international leader in printing, packaging, and logistic consumables since 2011, we recognize the significance of choosing the right labeling technology to enhance operational efficiency and product visibility globally.

Thermal transfer labels utilize a ribbon that creates a durable image by transferring ink onto the label surface, making them ideal for applications requiring longevity and resistance to environmental factors, such as moisture and heat. Conversely, direct thermal labels use heat-sensitive paper that develops an image when it passes under a thermal printhead. While direct thermal labels are often more cost-effective and suitable for short-term applications, they may fade over time, limiting their use in long-lasting applications.

In today's global market, both types of labels have unique advantages that cater to various industries. As businesses increasingly rely on reliable and efficient labeling solutions, selecting the appropriate type can significantly impact your supply chain and branding. At Sailing, we offer a wide range of high-quality labels tailored to meet diverse needs, backed by our extensive production capabilities in China and Malaysia. Partnering with us guarantees you access to the best labeling options tailored for your specific requirements, ensuring your products stand out in a competitive landscape.

How To Identify Thermal Transfer Labels Vs Direct Thermal Labels Products Stands Out Global Reach

| Label Type | Durability | Cost | Print Quality | Common Uses |

|---|---|---|---|---|

| Thermal Transfer Labels | High durability, resistant to abrasions | Higher cost due to ribbon usage | Excellent print quality and resolution | Product labeling, barcodes, inventory management |

| Direct Thermal Labels | Less durable, can fade over time | Lower cost, no ribbon required | Good print quality but can smear | Shipping labels, receipts, short-term labels |

Key Steps to Choosing Thermal Transfer Labels Vs Direct Thermal Labels Products Delivers Unmatched Quality Manufacturers You Can Rely On

J

James Thompson

The quality of this product exceeded my expectations. The team provided outstanding support throughout the purchasing process.

08

June

2025

C

Charlotte Hall

I am very pleased with my order! Their support team was very professional and knowledgeable.

21

June

2025

J

Jacob Gonzalez

This product delivers on quality! The after-sales support was knowledgeable and efficient.

25

May

2025

E

Ethan Scott

Quality is exceptional! Support team handled my concerns with utmost professionalism.

22

June

2025

L

Liam Thomas

Really top-quality product! The after-sales service was quick and very professional.

29

May

2025

J

Jackson Wright

I’m very impressed! The craftsmanship is excellent and customer service was very attentive.

13

May

2025

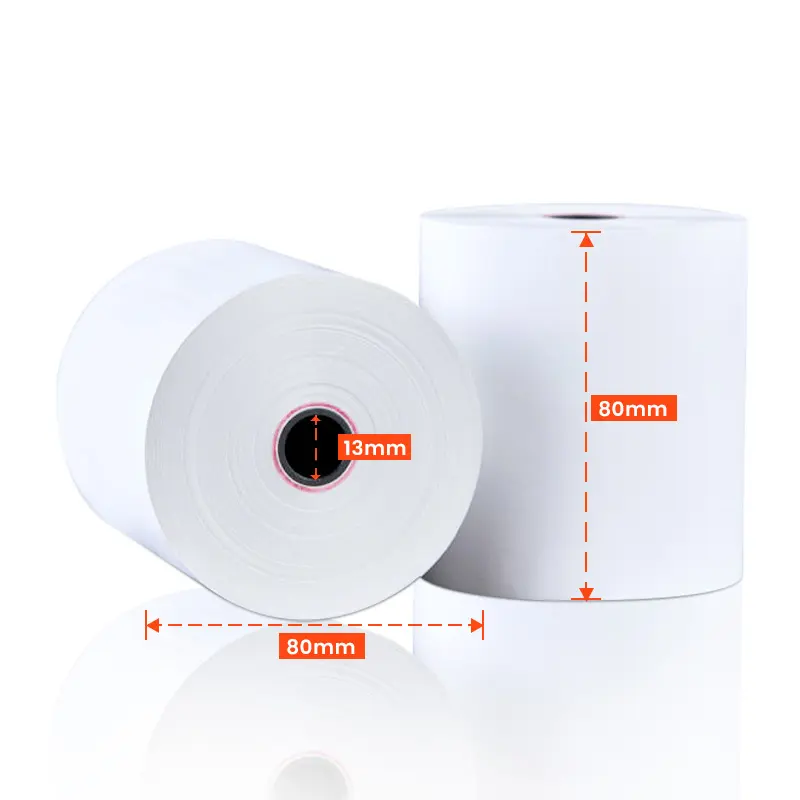

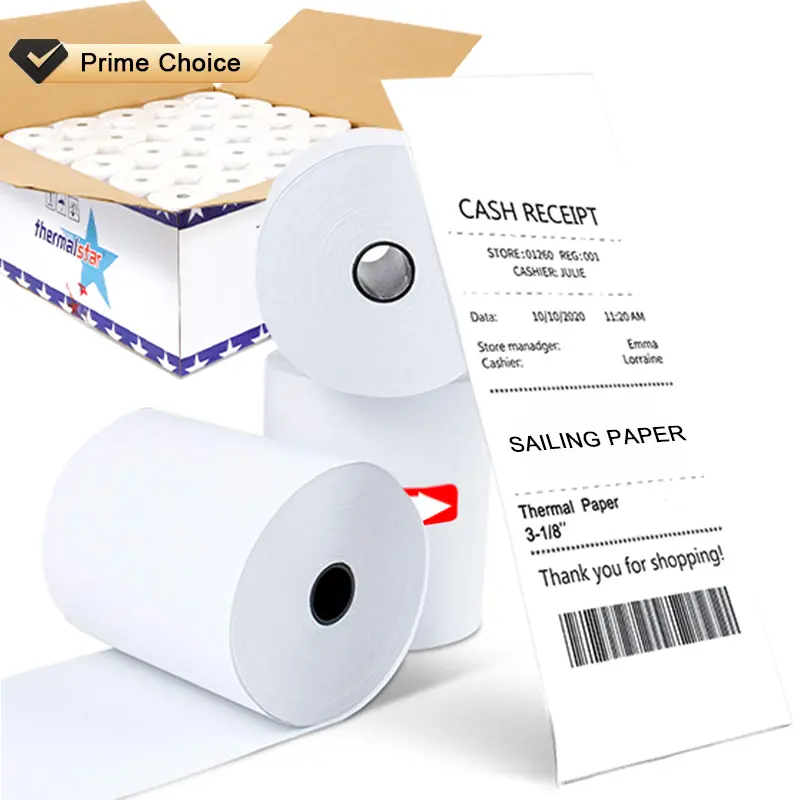

Thermal labels

Thermal labels