What Is The Difference Between Thermal And Direct Thermal Labels? OEM Quotes

When considering label options for your business, understanding What Is The Difference Between Thermal And Direct Thermal Labels is crucial. Thermal labels use a heat-activated coating for printing, while direct thermal labels rely solely on heat-sensitive material, eliminating the need for ink or toner. This distinction can significantly impact your operations and product choice, As a seasoned OEM professional, I appreciate how manufacturers often require reliable, long-lasting labels for their products. Direct thermal labels are great for short-term use—like shipping labels—while thermal labels offer durability for longer-term applications, such as product labeling, ShenZhen Sailing Paper Co., Ltd. specializes in providing high-quality thermal and direct thermal labels tailored to meet diverse needs. Choosing the right labels not only enhances your product appearance but also improves your operational efficiency. Let's explore our extensive range of products to find the perfect labels for your business today!

Best Chinese What Is The Difference Between Thermal And Direct Thermal Labels Now Trending Industry Leaders

In the fast-paced world of logistics and packaging, understanding the difference between thermal and direct thermal labels can significantly impact operational efficiency and cost-effectiveness. As an international group company established in 2011, Sailing has witnessed a remarkable evolution from a local paper converter to a global leader in printing and packaging solutions. Our production facilities in China and Malaysia enable us to meet the diverse needs of global buyers, offering high-quality labels tailored for various applications.

Thermal labels rely on a thermal printer that uses heat to transfer ink onto the label surface, producing vibrant, long-lasting prints. Conversely, direct thermal labels are heat-sensitive materials that change color when exposed to heat from the printer. This distinction leads to different usability scenarios; thermal labels are ideal for environments with varying temperatures or where durability is paramount, while direct thermal labels are suitable for shorter-term applications like shipping and retail.

With industry leaders trending towards more sustainable and efficient solutions, the choice between these label types becomes crucial for procurement managers. Sailing is committed to providing innovative packaging and logistic consumables that not only enhance operational processes but also align with environmentally friendly practices. Our extensive experience and global presence ensure that we are well-positioned to meet the evolving demands of the market. Discover the Sailing advantage as you navigate your labeling requirements and join the trend towards smarter, more sustainable solutions.

Best Chinese What Is The Difference Between Thermal And Direct Thermal Labels Now Trending Industry Leaders

| Feature | Thermal Labels | Direct Thermal Labels |

|---|---|---|

| Printing Method | Uses a thermal transfer ribbon to print | Uses heat to activate a chemical coating on the label |

| Durability | More robust, resistant to scratching and fading | Less durable, may fade or smear over time |

| Cost | Generally more expensive due to additional materials | Typically cheaper as it requires no ribbon |

| Print Quality | Higher print quality and resolution | Lower quality, may not be suitable for fine details |

| Suitable Applications | Ideal for long-term labeling solutions | Best for short-term or temporary applications |

Why Consider What Is The Difference Between Thermal And Direct Thermal Labels Guarantees Peak Performance Where Service Meets Innovation

S

Samantha Wright

The craftsmanship is outstanding. I felt valued as a customer due to their exceptional after-sales service.

13

May

2025

J

Jameson Harris

Great value for the quality! The service team was highly skilled and attentive to my needs.

10

June

2025

L

Lucas Hall

A fantastic product! Their customer service team stands out with their professionalism and skill.

29

May

2025

S

Sophia Reed

Fantastic purchase! The product is of high quality, and their service team is very professional.

07

June

2025

M

Madison Hughes

Very satisfied! The product quality and customer service exceeded my expectations.

15

June

2025

E

Ella Johnson

Great quality! The professionalism shown by their service staff was truly noteworthy.

23

June

2025

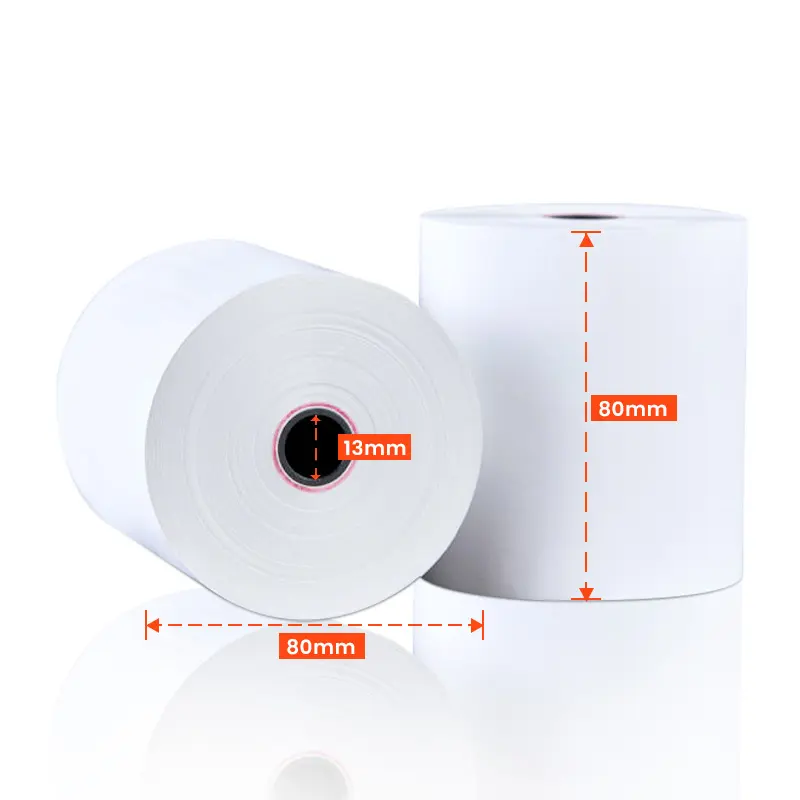

Thermal labels

Thermal labels