Compare Thermal Transfer vs Direct Thermal Labels: Key Insights for Exporters

Choosing the appropriate labeling solution for your business requires a clear understanding of the differences between thermal transfer labels and direct thermal labels. Each option has unique advantages tailored to different operational needs. Thermal transfer labels provide outstanding durability, making them ideal for long-term applications that demand resilience. In contrast, direct thermal labels are perfect for short-term uses, offering a cost-effective solution without compromising quality.Methods To choose Best Thermal Transfer Labels Vs Direct Thermal Application Where Service Meets Innovation

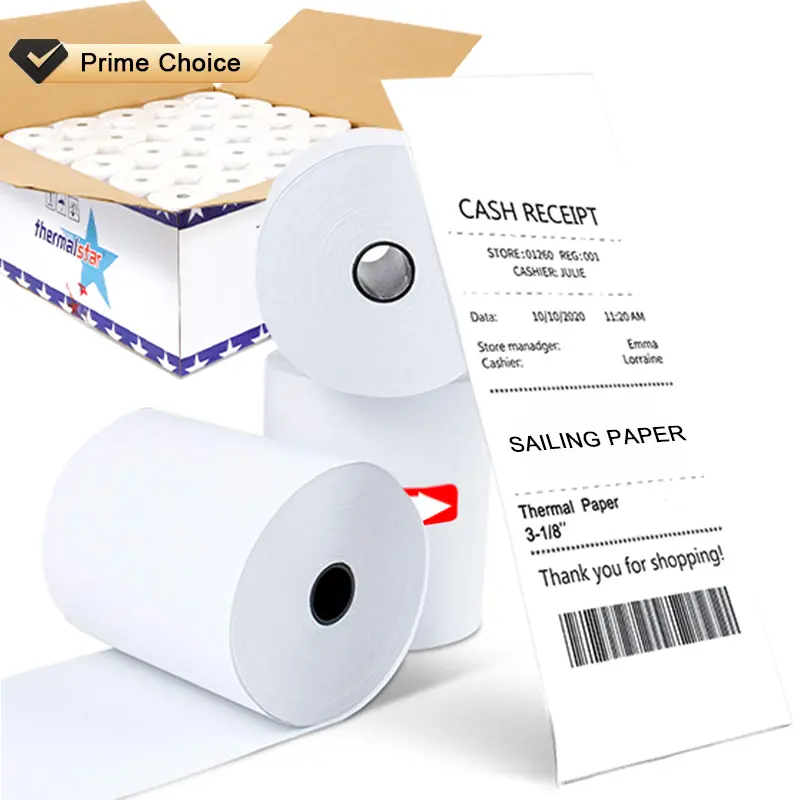

When it comes to selecting the best thermal transfer labels versus direct thermal applications, global buyers must consider multiple factors to ensure they meet their operational needs while embracing innovation. Since our establishment in 2011, Sailing has evolved from a local paper converter to an international leader in printing, packaging, and logistic consumables. Our facilities in China and Malaysia allow us to offer a wide range of high-quality labeling solutions tailored to diverse industries.

Thermal transfer labels are ideal for applications requiring durability and longevity, making them perfect for environments exposed to scratches, chemicals, and extreme temperatures. In contrast, direct thermal applications, while typically more cost-effective, are better suited for short-term labeling needs where exposure to sunlight or heat is minimal. Understanding these differences empowers buyers to make informed decisions based on their specific labeling requirements.

At Sailing, we prioritize innovation in our production processes, ensuring that our clients receive cutting-edge solutions that enhance their operational efficiency. By choosing the right labeling method and collaborating with a trusted partner like us, global buyers can achieve remarkable results in their supply chain and branding efforts, creating a seamless connection between service and innovation.

Methods To Choose Best Thermal Transfer Labels Vs Direct Thermal Application Where Service Meets Innovation

| Criteria | Thermal Transfer Labels | Direct Thermal Application |

|---|---|---|

| Durability | High; resistant to scratches and chemicals | Moderate; may fade over time with exposure to heat |

| Print Quality | Excellent; sharp, high-resolution images | Good; suitable for standard barcodes and text |

| Cost | Generally higher due to ribbon cost | Lower; no ribbon needed |

| Speed | Moderate; requires time for ribbon transfer | High; direct printing method |

| Applications | Ideal for logistics, shipping, and industrial uses | Suitable for retail, tickets, and short-term labels |

| Environmental Resistance | Good; weatherproof and UV resistant options | Limited; not suitable for outdoor or extreme conditions |

How-To Guide Best Thermal Transfer Labels Vs Direct Thermal Service Exceeds Industry Benchmarks

A

Amelia Young

This purchase was a great decision. The quality is excellent and the service was prompt and professional.

15

May

2025

V

Victoria Wright

The quality of this product is fantastic! I appreciated the professionalism of the team.

01

July

2025

A

Alexander Hughes

Such great quality! Their customer service team made the whole process effortless.

18

June

2025

E

Ella White

Exceptional quality! Their support team after purchase was very friendly and knowledgeable.

05

July

2025

M

Michael Brooks

High-quality product! The support team was knowledgeable and extremely helpful.

27

May

2025

Z

Zoe Gonzalez

Absolutely outstanding! The quality of the product and the service were both exemplary.

16

May

2025

Thermal labels

Thermal labels