Converting Thermal Transfer Labels to Direct Thermal: CE Certified Prices & Insights

Curious about converting thermal transfer labels to direct thermal labels? At ShenZhen Sailing Paper Co., Ltd., we provide high-quality label solutions tailored to your specific needs. Our experts are here to simplify your label choices and assist you with the conversion process. Contact us today for personalized guidance and support!

Step-by-Step Guide To Can Thermal Transfer Label Be Converted To Direct Thermal Label Product Outperforms the Competition Trusted by Pros

In the competitive landscape of printing and packaging, understanding the differences between thermal transfer labels and direct thermal labels can significantly impact your business operations. At Sailing, we've dedicated ourselves to not only producing high-quality printing and packaging solutions since our establishment in 2011 but also to educating our partners around the globe on how to optimize their labeling choices. Our international reach, with production capabilities in both China and Malaysia, positions us as a trusted source for labeling solutions that outperform the competition.

Converting thermal transfer labels to direct thermal labels may seem challenging, but with the right guidance, it can enhance your efficiency and reduce costs. Direct thermal labels eliminate the need for ribbon supplies, simplifying your labeling process and reducing operational expenses. Furthermore, these labels are designed to withstand various environmental factors, making them versatile for different applications. Professionals in the industry appreciate the reliability and efficiency of direct thermal labels, which can be seamlessly integrated into existing systems, providing a competitive edge.

At Sailing, we believe that informed decisions lead to successful business outcomes. We encourage global buyers to explore the advantages of switching to direct thermal labels and leverage our expertise in printing and packaging consumables. By choosing Sailing, you not only receive high-quality products but also access valuable insights that can drive your business forward in today’s fast-paced market.

Step-by-Step Guide To Can Thermal Transfer Label Be Converted To Direct Thermal Label Product Outperforms the Competition Trusted by Pros

| Label Type | Printing Technology | Durability | Cost Per Label | Best Use Cases |

|---|---|---|---|---|

| Thermal Transfer | Thermal Transfer Printing | High (3-5 years) | $0.05 | Long-term labeling, high-quality standards |

| Direct Thermal | Direct Thermal Printing | Medium (6-12 months) | $0.03 | Shipping labels, short-term applications |

| Hybrid Labels | Combination of Both | Variable (depends on application) | $0.06 | Versatile situations, mixed environments |

Champions of Can Thermal Transfer Label Be Converted To Direct Thermal Label Product Pioneers in the Field Now Trending

H

Harper King

Great quality and performance! The team was professional, making the whole process seamless.

30

June

2025

A

Alexander Hughes

Such great quality! Their customer service team made the whole process effortless.

18

June

2025

O

Olivia Young

Absolutely delighted! The quality is remarkable and the staff was incredibly helpful.

26

May

2025

A

Ava Green

Quality and service both exceeded my expectations! The team was highly responsive and informative.

07

May

2025

E

Ella Williams

I’m impressed! The product quality and after-sales support crew were both top-notch.

11

June

2025

A

Avery Morgan

The product quality is fantastic! Their customer service agents were very responsive and helpful.

10

June

2025

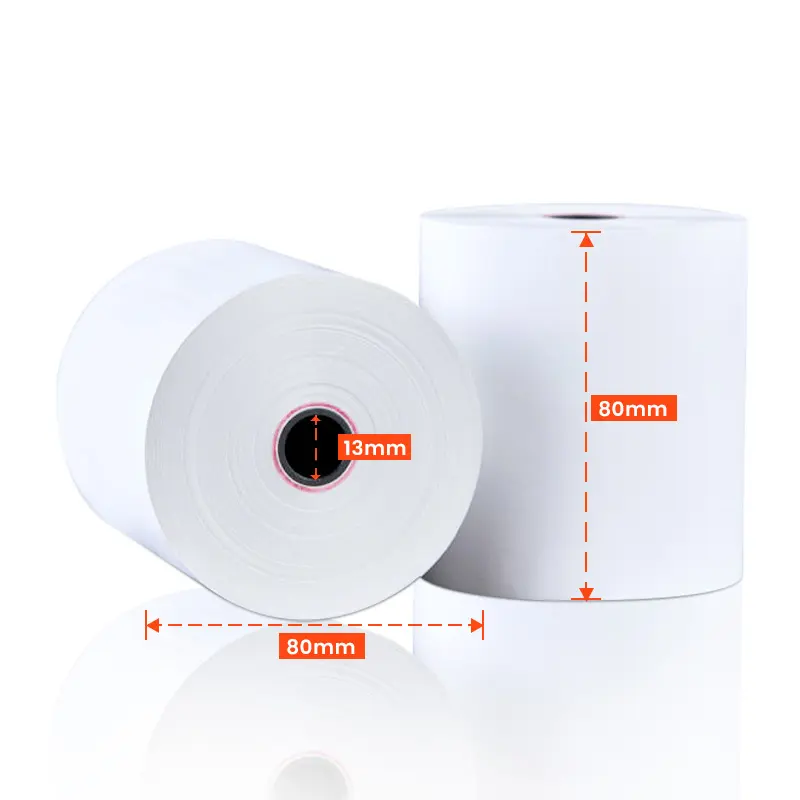

Thermal labels

Thermal labels