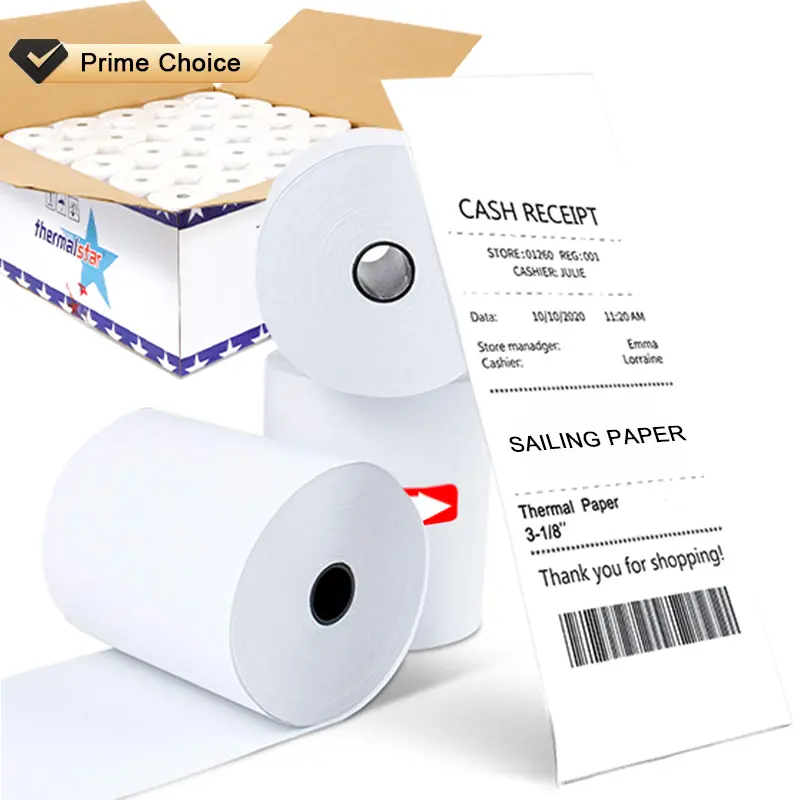

OEM Thermal Paper Roll Manufacturers | Quality Products from Trusted Factories

If you need reliable manufacturers of thermal paper rolls, you've found the ideal source. We provide high-quality thermal paper rolls at competitive prices, designed for businesses that demand durable and efficient printing solutions. Our extensive industry experience allows us to offer affordable options without sacrificing quality. Get the best thermal paper rolls for your business without straining your budget. Count on us to meet all your thermal paper roll needs. Contact us today to establish a lasting partnership!

Must-Know Tips For manufacturers thermal paper roll From Concept to Delivery Manufacturer

When it comes to sourcing thermal paper rolls, manufacturers must navigate a series of critical steps, from concept to delivery. Understanding these processes can enhance your purchasing experience and ensure you receive high-quality products. At Sailing, with over a decade of expertise in the paper industry and production facilities in China and Malaysia, we have developed essential insights to share.

First, it's vital to clearly define your requirements. Consider the specifications of the thermal paper you need, such as width, roll diameter, and coating type. Our production capabilities allow us to customize thermal paper rolls to fit a variety of applications, ensuring that every product meets the unique needs of our clients. Additionally, always request samples to evaluate the quality before making large orders. Quality assurance is paramount, and we prioritize this at every stage of production.

Finally, streamline your logistics. Sailings’ international presence facilitates efficient shipping and delivery processes, minimizing delays. Collaborating with a manufacturer who understands the global market dynamics can significantly impact your supply chain efficiency. As you plan your next thermal paper order, remember these must-know tips to make an informed and impactful decision. Partnering with a reliable manufacturer like Sailing can transform your sourcing strategy and drive your operations towards success.

Must-Know Tips For Manufacturers Thermal Paper Roll From Concept to Delivery

| Dimension | Specification | Tips |

|---|---|---|

| Width | Standard options include 57mm, 80mm, 112mm | Choose width based on printer compatibility and application needs. |

| Core Size | Common sizes are 12mm, 25mm, and 40mm | Ensure core size matches printing equipment for optimal performance. |

| Caliper | Typically ranges from 55 to 90 microns | Select caliper based on durability needs and printer specifications. |

| Paper Type | Thermal, bond, and carbonless | Consider application and print quality; thermal paper is ideal for receipts. |

| Print Technology | Direct thermal or thermal transfer | Ensure the selected paper is appropriate for the chosen print technology. |

| Packaging | Individual rolls vs. bulk packaging | Choose packaging style based on storage and dispensing convenience. |

| Environmental Considerations | Recycled options available | Opt for environmentally friendly paper to reduce ecological impact. |

| Supplier Reliability | Evaluate based on reviews and delivery times | Choose a trusted supplier to avoid disruptions in supply chain. |

Finding Your Perfect Match manufacturers thermal paper roll Pioneers in the Field Ahead of the Curve

A

Amelia Young

This purchase was a great decision. The quality is excellent and the service was prompt and professional.

15

May

2025

J

Jacob Gonzalez

This product delivers on quality! The after-sales support was knowledgeable and efficient.

25

May

2025

Z

Zoe Mitchell

I love this product! The support team showed great understanding and professionalism throughout.

24

June

2025

O

Olivia Young

Absolutely delighted! The quality is remarkable and the staff was incredibly helpful.

26

May

2025

N

Natalie Torres

Incredible quality! Their support staff was prompt and skilled in addressing my questions.

01

June

2025

E

Elijah Anderson

Amazing product quality! Their service team went above and beyond to assist me.

13

May

2025

Thermal labels

Thermal labels