Top CE Certified Manufacturers of Nine Hazardous Materials Labels

At ShenZhen Sailing Paper Co., Ltd., we understand the importance of high-quality hazardous materials warning labels. Our labels are designed to be clear, durable, and compliant with CE certification standards, ensuring that your workplace maintains safety and regulatory compliance. With a wide selection of customizable options for various hazardous materials, we prioritize competitive pricing without sacrificing quality. By choosing us, you engage with a manufacturer dedicated to transparency and customer satisfaction. Reach out to us for quotes or inquiries about our manufacturing process. Prioritize safety with our reliable warning labels!

10 Essential Tips For Nine Different Hazardous Materials Warning Labels Manufacturer Winning in 2025 Products

In an increasingly globalized market, understanding the essential aspects of hazardous materials warning labels is paramount for manufacturers aiming to thrive in 2025. As a trusted leader in printing and packaging solutions since 2011, Sailing has watched the industry evolve and has adapted to meet the unique needs of clients. With production facilities in both China and Malaysia, we provide high-quality, reliable products that ensure compliance and safety in logistics and handling.

First and foremost, it’s crucial to standardize your warning labels according to international regulations. As different regions enforce varying guidelines, staying updated with changes aids in avoiding legal pitfalls and shipping delays. Next, consider utilizing durable materials that withstand harsh chemical environments and maintain legibility. Color contrast and symbol clarity are vital in ensuring the labels are easily interpreted, reducing the risk of accidents and ensuring workplace safety.

Additionally, leveraging technology such as QR codes can enhance the effectiveness of your warning labels. This can lead to instant access to detailed safety data sheets, thereby providing vital information at a moment’s notice. Manufacturers should also prioritize sustainability in their label production, resonating with the global shift towards eco-friendly solutions. By implementing these essential tips, manufacturers can not only comply with regulations but also build a strong reputation and drive success in the competitive market of hazardous materials management.

10 Essential Tips For Nine Different Hazardous Materials Warning Labels Manufacturer Winning in 2025 Products

| Tip No. | Tip Description | Material Type | Regulatory Compliance | Design Considerations |

|---|---|---|---|---|

| 1 | Use clear and concise language on labels. | Flammable liquids | OSHA, NFPA | High contrast text and background. |

| 2 | Implement color coding for hazard levels. | Corrosive substances | GHS | Use symbols and graphics effectively. |

| 3 | Test label durability under various conditions. | Toxic materials | EPA | Consider moisture and temperature resistance. |

| 4 | Include emergency contact information. | Radioactive materials | NRC | Easy access to vital information. |

| 5 | Train staff on proper labeling techniques. | Oxidizers | ANSI | Focus on clarity for end users. |

| 6 | Review international standards for labeling. | Biohazardous materials | WHO, CDC | Consider cultural differences in design. |

| 7 | Update labels for new safety protocols. | Aerosols | DOT | Reflect trends in safety regulations. |

| 8 | Conduct regular audits of labeling practices. | Compressed gases | ISO | Ensure compliance with evolving standards. |

| 9 | Utilize technology for smart labeling solutions. | Industrial chemicals | REACH | Incorporate QR codes for additional info. |

Methods To choose Nine Different Hazardous Materials Warning Labels Manufacturer Application Your Trusted OEM Partner

C

Christopher Lee

Fantastic product! The support team demonstrated a high level of professionalism and expertise.

12

June

2025

Z

Zachary Cole

This product speaks for itself in terms of quality. The support was insightful and very attentive.

22

June

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

I

Isabella Johnson

Thrilled with my order! The quality is excellent, and the staff’s professionalism is outstanding.

29

June

2025

B

Benjamin Wright

Really high-quality product! The professionalism from the service team was a pleasant surprise.

29

June

2025

H

Henry Adams

Exceptional quality! Their team responded promptly to my inquiries, showcasing great professionalism.

23

June

2025

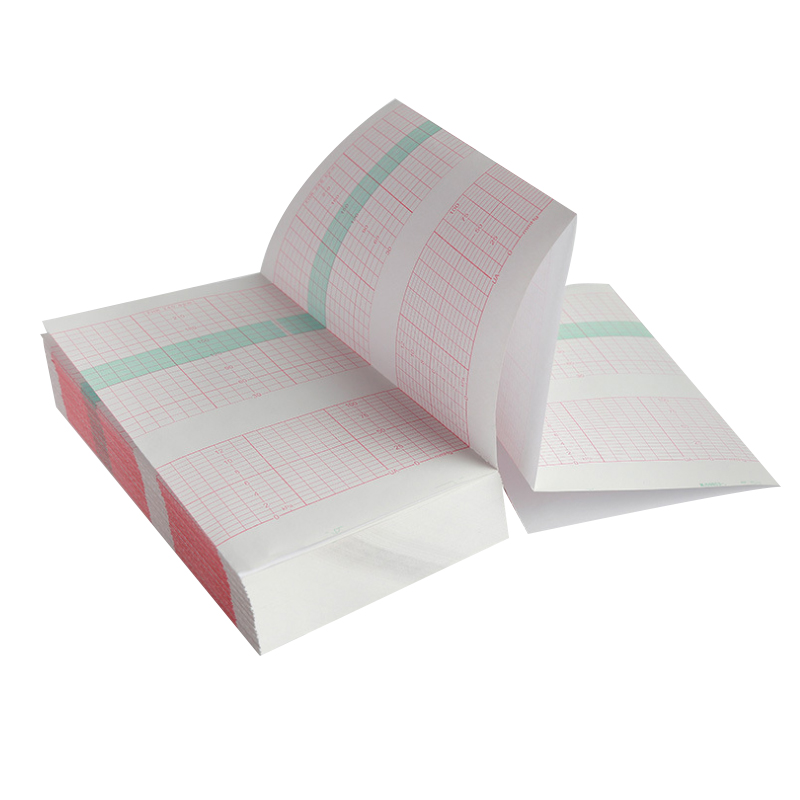

Thermal labels

Thermal labels