Affordable ODM Thermal Transfer & Direct Thermal Labels Wholesale Price List

At ShenZhen Sailing Paper Co., Ltd., we recognize that choosing the right manufacturer is crucial for your success. Our team is ready to offer competitive quotes and valuable insights on how our labels can elevate your brand visibility. Whether you're just starting out or have an established presence, we are committed to providing outstanding service and tailored products that meet your unique business needs. Contact us for a quote, and let’s collaborate to create the perfect labeling solutions for your project.Quick Tips To ODM Can Thermal Transfer Label Be Converted To Direct Thermal Label Manufacturer Is The Best Delivers Unmatched Quality

In the dynamic world of printing and packaging, the demand for versatile label solutions is ever-growing. As a global leader in the industry since 2011, Sailing has established itself as a trusted provider of high-quality printing, packaging, and logistic consumables. One question that often arises for businesses is whether thermal transfer labels can be converted to direct thermal labels. Understanding the fundamental differences and applications of these label types is crucial for procurement professionals seeking optimal solutions for their operations.

Thermal transfer labels rely on a ribbon to transfer ink onto the label material, offering durability and resistance to fading, making them ideal for long-term applications. On the other hand, direct thermal labels use heat-sensitive material that produces an image when exposed to a thermal printhead. While both types have their advantages, businesses must assess their specific needs—such as shelf life, environmental conditions, and printing speed—when choosing between them. Our expertise as an ODM (Original Design Manufacturer) allows us to deliver unmatched quality in both product categories, ensuring our clients receive tailored solutions that enhance their operations.

Choosing the right manufacturer is key to achieving superior label performance. At Sailing, we pride ourselves on our international production capabilities based in China and Malaysia, enabling us to offer competitive pricing without compromising quality. Our commitment to innovation and excellence makes us the best choice for global buyers looking for reliable label solutions that meet their diverse needs. By partnering with us, you are not just opting for a product; you are embracing a partnership designed to support your growth in an increasingly competitive market.

Quick Tips To ODM Can Thermal Transfer Label Be Converted To Direct Thermal Label Manufacturer Is The Best Delivers Unmatched Quality

| Tip Number | Tip Description | Conversion Feasibility | Quality Indicator | Recommended Use Cases |

|---|---|---|---|---|

| 1 | Understand the differences between thermal transfer and direct thermal labels. | Possible, but requires appropriate materials. | High test prints recommended. | Logistics, shipping labels. |

| 2 | Choose a manufacturer with a good reputation for quality. | Not applicable. | Consistency in print quality. | Retail, product labels. |

| 3 | Test thermal transfer labels under various environmental conditions. | Yes, with suitable testing. | Durability over time. | Warehouse management. |

| 4 | Ensure compatibility of hardware for label printing. | Essential for operations. | Clarity and sharpness. | Healthcare, pharmaceuticals. |

| 5 | Evaluate cost-effectiveness before conversion. | Recommended to assess. | Cost per label. | Bulk shipping, inventory management. |

Methods To choose ODM Can Thermal Transfer Label Be Converted To Direct Thermal Label Manufacturer Trusted by Pros Outperforms the Competition

L

Lucas Allen

Superior product quality! The customer service representatives were incredibly helpful and informative.

25

May

2025

C

Chloe Hill

Highly satisfied with my order! The after-sales service was professional and prompt.

19

June

2025

B

Benjamin Wright

Really high-quality product! The professionalism from the service team was a pleasant surprise.

29

June

2025

S

Samuel Reed

Amazing purchase! The product quality is true to description, and the service was professional and helpful.

13

June

2025

C

Cameron Lee

Outstanding product quality! The team provided insightful and prompt responses.

20

May

2025

S

Sophia Adams

Absolutely satisfied! The product quality matched my expectations, and the service was very personalized.

11

May

2025

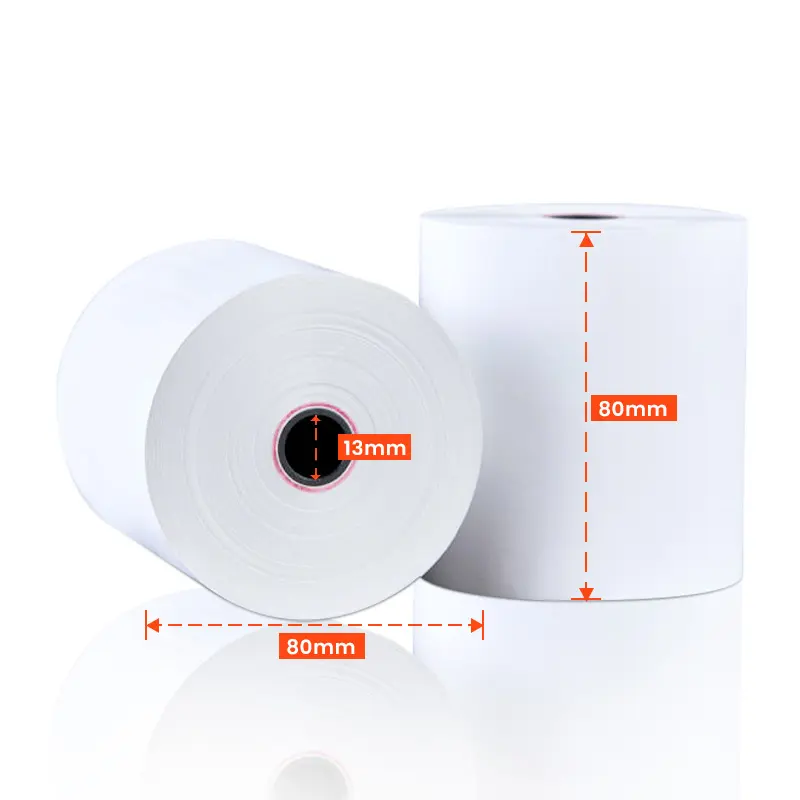

Thermal labels

Thermal labels