ODM Thermal Transfer vs Direct Thermal Labels: Key Differences and Supplier Insights

Understanding the differences between ODM thermal transfer labels and direct thermal labels is essential for making informed decisions in your labeling needs. ODM thermal transfer labels provide exceptional durability and vibrant colors, making them suitable for OEM applications across various industries. In contrast, direct thermal labels offer an economical solution for short-term labeling tasks, requiring no ink and enabling swift turnarounds. At ShenZhen Sailing Paper Co., Ltd., we focus on delivering high-quality products to meet your exact specifications. Whether your requirements involve high-volume production or tailored labeling solutions, we have the expertise and range to enhance your operations and drive your business growth.

Don't Miss These ODM Thermal Transfer Labels Vs Direct Thermal Exceeds Industry Benchmarks Stands Out

In the ever-evolving landscape of printing and packaging solutions, the choice between ODM thermal transfer labels and direct thermal labels has become crucial for global buyers looking to optimize their operations. At Sailing, we have recognized the importance of these technologies since our establishment in 2011 and have positioned ourselves as an international leader in this domain. With state-of-the-art production facilities in both China and Malaysia, we deliver top-notch products that not only meet but often exceed industry benchmarks.

ODM thermal transfer labels offer superior durability and image quality, making them ideal for applications requiring longevity and precision. In contrast, direct thermal labels provide a more cost-effective solution for short-term labeling needs, perfect for applications that do not require a long lifespan. Understanding the nuances of each option can significantly impact inventory management, operational efficiency, and overall cost-effectiveness. At Sailing, our expertise in manufacturing and exporting these consumables enables us to cater to diverse industry needs, ensuring you make an informed decision that aligns with your business goals.

As a trusted partner in the printing, packaging, and logistics industry, Sailing provides not just products, but also tailored solutions that help you stay ahead of the competition. Whether you opt for ODM thermal transfer labels or direct thermal labels, our commitment to quality and innovation ensures you receive the best value for your investment. Don’t miss out on the opportunity to elevate your labeling strategy with Sailing's robust offerings, designed to meet the dynamic demands of businesses worldwide.

Don't Miss These ODM Thermal Transfer Labels Vs Direct Thermal Exceeds Industry Benchmarks Stands Out

| Label Type | Print Method | Durability (Years) | Industry Benchmark | Cost per Label (USD) | Best Use Cases |

|---|---|---|---|---|---|

| ODM Thermal Transfer Labels | Thermal Transfer | 5-7 | High Scratch and Fade Resistance | $0.08 | Warehouse Management, Product Labeling |

| Direct Thermal Labels | Direct Thermal | 1-3 | Ideal for Short-Term Use | $0.05 | Shipping Labels, Retail Tags |

Ultimate Guide To ODM Thermal Transfer Labels Vs Direct Thermal Guarantees Peak Performance Your Trusted OEM Partner

M

Matthew Rodriguez

Impressive quality and design! I appreciate the professional manner in which my inquiries were handled.

04

July

2025

G

Grace Nelson

Wonderful quality! Their dedicated support team resolved all my queries without hesitation.

22

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

C

Carter Rivera

Great product! The after-sales service was really efficient and professionally handled.

22

June

2025

S

Samuel Reed

Amazing purchase! The product quality is true to description, and the service was professional and helpful.

13

June

2025

C

Chloe Young

Wonderful quality! The knowledge of their support staff really helped me with my purchase.

27

June

2025

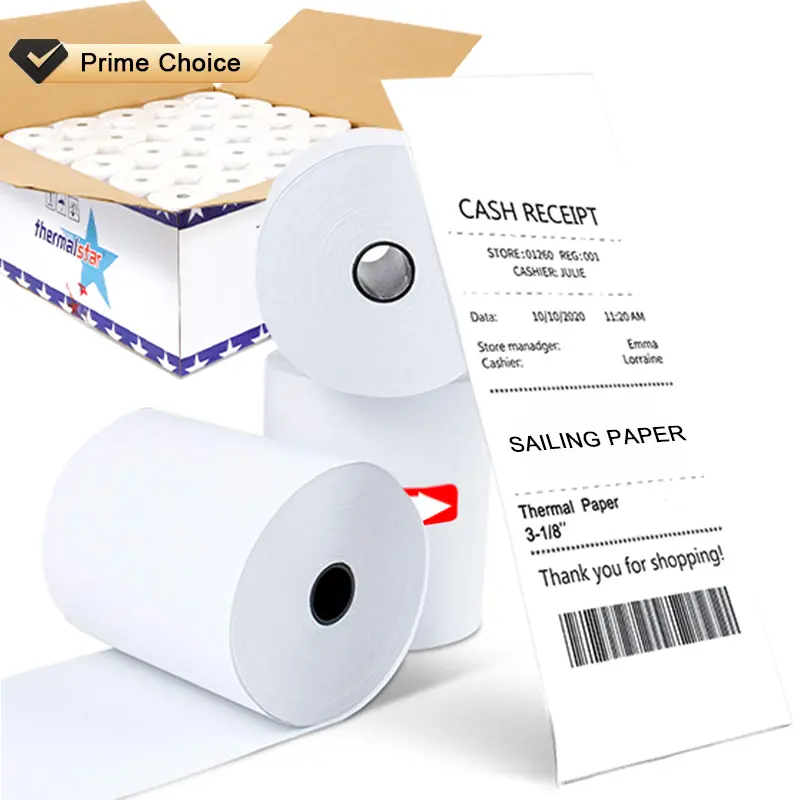

Thermal labels

Thermal labels