OEM Thermal Transfer vs. Laser Labels: Durability Analysis & CE Certification Insights

When evaluating label solutions, it's crucial to understand the differences in durability between OEM thermal transfer labels and laser labels. Thermal transfer labels excel in resisting scratches, moisture, and chemicals, making them ideal for challenging environments. In contrast, laser labels are often more affordable and provide excellent print quality but may not withstand tough conditions as effectively. Comparing quotes and assessing price lists from various suppliers can help identify the optimal choice for your needs. At ShenZhen Sailing Paper Co., Ltd., we offer a diverse selection of label solutions tailored for specific applications while ensuring high durability and quality. Let's discuss how we can fulfill your label requirements.Best Way To OEM Thermal Transfer Vs Laser Label Durability Supplier Global Reach

When it comes to selecting the right labels for your products, the choice between OEM thermal transfer and laser labels can significantly impact durability and efficiency. At Sailing, established in 2011, we have evolved from a local paper converter to an influential international group, with production facilities in both China and Malaysia. Our extensive experience in manufacturing high-quality printing, packaging, and logistic consumables positions us as a leading supplier for global procurement needs.

Thermal transfer labels offer superior durability, making them ideal for applications requiring resistance to environmental factors such as moisture, sunlight, and abrasion. Their long-lasting quality ensures that your branding remains intact, fostering brand loyalty and recognition. On the other hand, laser labels provide excellent print quality and versatility, making them suitable for on-demand printing needs. Finding the right balance between these two options depends on your specific requirements, and at Sailing, we are committed to helping you make the best choice tailored to your operational needs.

Our global reach allows us to serve clients across various industries efficiently. With a dedication to quality control and customer satisfaction, Sailing ensures that every product meets international standards, providing peace of mind for our partners. By choosing us as your supplier, you not only gain access to top-tier label solutions but also a partnership built on reliability and expertise in the printing and packaging sector. Let us help you enhance your brand with durable labeling solutions that stand the test of time.

Best Way To OEM Thermal Transfer Vs Laser Label Durability Supplier Global Reach

| Supplier Type | Label Type | Durability Rating (Years) | Global Reach (Countries) | Typical Applications |

|---|---|---|---|---|

| OEM Thermal Transfer | Thermal Transfer Labels | 5-10 | 30 | Warehouse, Manufacturing |

| Laser Label | Laser Printed Labels | 3-5 | 40 | Retail, Logistics |

| OEM Thermal Transfer | Synthetic Thermal Labels | 7-12 | 25 | Chemical, Pharmaceuticals |

| Laser Label | Polyester Laser Labels | 4-6 | 35 | Electronics, Automotive |

Best Options For OEM Thermal Transfer Vs Laser Label Durability Where Innovation Meets 2025 More Than a Supplier - A Partner

E

Emma Johnson

Excellent craftsmanship! I truly appreciate the prompt and professional service from the support team.

14

June

2025

A

Ava Anderson

Top-notch quality! The representatives were attentive and addressed my concerns promptly.

03

June

2025

L

Lucas Allen

Superior product quality! The customer service representatives were incredibly helpful and informative.

25

May

2025

M

Mason Carter

Exceptional product quality! The after-sales personnel were exemplary in their professionalism.

13

May

2025

V

Victoria Wright

The quality of this product is fantastic! I appreciated the professionalism of the team.

01

July

2025

C

Chloe Young

Wonderful quality! The knowledge of their support staff really helped me with my purchase.

27

June

2025

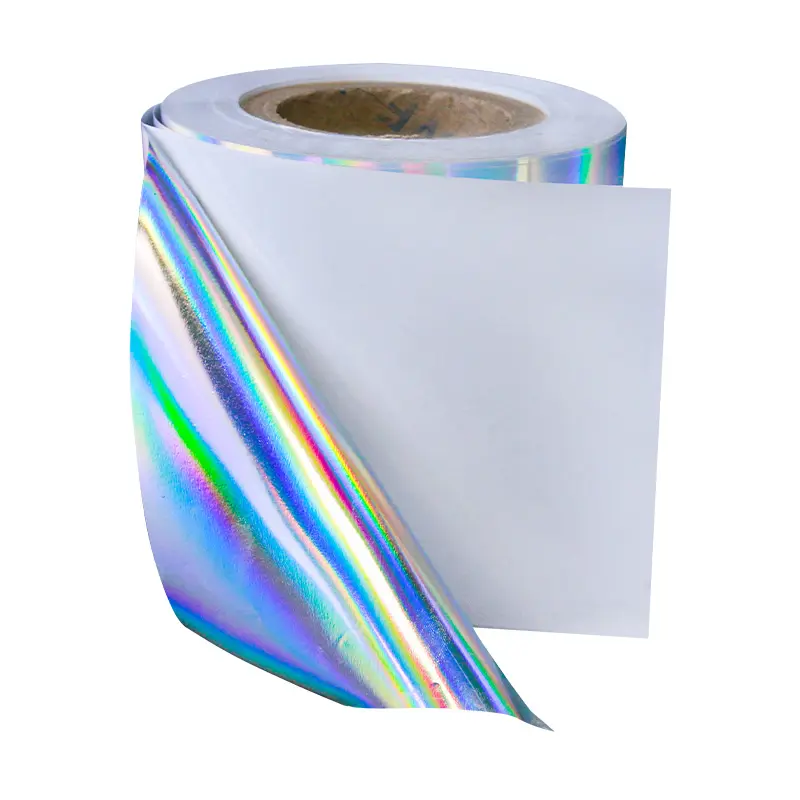

Thermal labels

Thermal labels