Essential Tips for CE Certification & Cost Quotes on Slitting Machine Preparation

Efficiency and safety are paramount when operating slitting machines, making thorough preparation essential. As a B2B buyer, I understand the value of collaborating with a dependable supplier that offers high-quality slitting machines. I prioritize partners who excel in machine setup and operational support. Before engaging these machines, I ensure blades are sharpened, materials are properly aligned, and all safety protocols are adhered to. This diligent approach maximizes production efficiency and minimizes downtime. At ShenZhen Sailing Paper Co., Ltd., we provide robust slitting machines tailored to diverse production needs. Our dedication to quality and excellent service positions us as a leading choice in the industry. For wholesale inquiries or information about our comprehensive range of slitting machine products, please contact us. Proper preparation, along with the right machinery, is key to achieving success in operations.

Decoding Slitting Machine Preparation Before Operation Outperforms the Competition Now Trending

In the competitive landscape of manufacturing, understanding the preparation processes of machinery is crucial for optimizing performance and maintaining an edge in the global market. At Sailing, we recognize that the efficiency of our slitting machines directly influences the quality of our printed and packaged products. Since our establishment in 2011, we have evolved from a local paper converter to an international enterprise with production facilities in both China and Malaysia. This growth has allowed us to hone our processes and streamline machine preparation, ensuring that our products surpass the expectations of global buyers.

Decoding the intricacies of slitting machine preparation is not just about enhancing productivity; it's about delivering reliability and consistency that global customers demand. By implementing advanced training for our operators and investing in cutting-edge technology, we ensure that our machinery operates at peak performance. These practices translate into superior quality control and reduced waste in our production lines, enabling us to provide top-notch printing, packaging, and logistic consumables that meet international standards.

As we continue to innovate and refine our operations, we invite global procurement professionals to explore how Sailing’s commitment to excellence can meet their needs. By prioritizing the preparation of our slitting machines, we not only enhance our competitive standing but also solidify our reputation as a trustworthy partner in the international market.

Decoding Slitting Machine Preparation Before Operation Outperforms the Competition Now Trending

| Parameter | Description | Value | Industry Standard |

|---|---|---|---|

| Machine Speed | Speed of operation in meters per minute | 150 m/min | 120 m/min |

| Material Waste | Percentage of material wasted during slitting | 2% | 5% |

| Setup Time | Time taken to set up the machine | 30 minutes | 45 minutes |

| Operational Downtime | Total downtime during operations | 10% | 15% |

| Cut Accuracy | Precision of the slitting process | ±0.1 mm | ±0.3 mm |

Key Steps to Choosing Slitting Machine Preparation Before Operation Service Factory-Direct Excellence

D

David Wilson

High-quality materials and excellent performance. The customer support team was highly professional and responsive.

08

June

2025

S

Sofia Mitchell

Absolutely wonderful quality! Their team demonstrated unparalleled professionalism throughout.

01

July

2025

L

Lucy Thompson

I am extremely satisfied! The service staff displayed remarkable professionalism and skill.

02

July

2025

O

Owen Johnson

Excellent quality! Their customer service team was very efficient and polite.

14

May

2025

A

Addison Clark

I am thoroughly impressed! The product quality is fantastic and the service was impeccable.

06

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

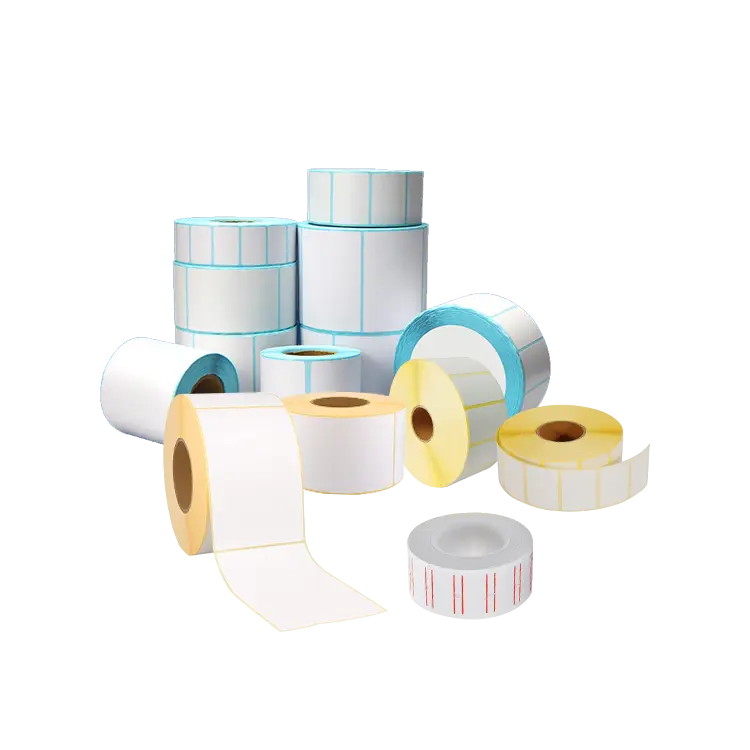

Thermal labels

Thermal labels