Top Thermal Label Exporters for High-Quality Production Solutions

ShenZhen Sailing Paper Co., Ltd. specializes in high-quality thermal label production with customized ODM solutions to meet your unique labeling needs. As a seasoned exporter in the industry, we are committed to delivering exceptional products that ensure efficiency and precision. Our thermal labels are designed for durability and performance across various applications, making them ideal for businesses in retail, logistics, and beyond. We prioritize quality and customer satisfaction by working closely with clients to achieve outstanding results that align with their brand standards. Partner with us to elevate your labeling solutions.

Best Strategies For Thermal Label Production Your Trusted OEM Partner Dominates

In the rapidly evolving world of thermal label production, choosing the right OEM partner is crucial for global buyers seeking both quality and reliability. Since our establishment in 2011, Sailing has transformed from a local paper converter into an international powerhouse, with production facilities in China and Malaysia. Our dedication to high-quality printing, packaging, and logistic consumables sets us apart as a trusted partner for businesses seeking innovative solutions.

To maximize efficiency and effectiveness in thermal label production, we recommend several key strategies. First, understanding the specific needs of your market is essential; custom solutions can vastly improve efficiency and customer satisfaction. Second, leveraging cutting-edge technologies in production helps ensure that our labels meet international quality standards while enabling quick turnaround times. Finally, maintaining robust communication channels between buyers and OEM partners fosters collaboration, allowing for timely adjustments and improvements in product offerings.

By partnering with Sailing, you not only gain access to superior products but also benefit from our extensive experience and commitment to excellence. With our deep understanding of both the printing and logistics sectors, we stand ready to support your business needs and drive your success in the global marketplace. Let us show you how our expertise can elevate your thermal label production and secure your position as a leader in your industry.

Best Strategies For Thermal Label Production

| Strategy | Description | Benefits | Expected Outcome |

|---|---|---|---|

| Material Selection | Choose high-quality thermal materials that ensure optimal printing. | Improved print clarity and durability. | Longer-lasting labels with better performance. |

| Printer Calibration | Regularly calibrate printers to maintain accuracy and reliability. | Fewer printing errors and waste. | Cost savings and efficiency. |

| Design Optimization | Create label designs that maximize printing efficiency. | Enhanced visuals and better readability. | Improved customer satisfaction. |

| Quality Control | Implement a rigorous quality control process to monitor output. | Consistent product quality and reliability. | Reduced return rates and increased trust. |

| Sustainable Practices | Utilize eco-friendly materials and processes. | Reduced environmental impact. | Positive brand image and compliance with regulations. |

Step-by-Step Guide Thermal Label Production Industry Giant Delivers Unmatched Quality

L

Lily Clark

The quality is impressive! Customer support was friendly and knowledgeable.

14

May

2025

A

Alexander Hughes

Such great quality! Their customer service team made the whole process effortless.

18

June

2025

G

Gabriel Martinez

Wonderful quality! The professionalism of their customer service was quite impressive.

18

June

2025

E

Ella Williams

I’m impressed! The product quality and after-sales support crew were both top-notch.

11

June

2025

H

Henry Adams

Exceptional quality! Their team responded promptly to my inquiries, showcasing great professionalism.

23

June

2025

G

Grace Hall

Impressive quality! The professionalism of the service team made a positive impact on my experience.

24

May

2025

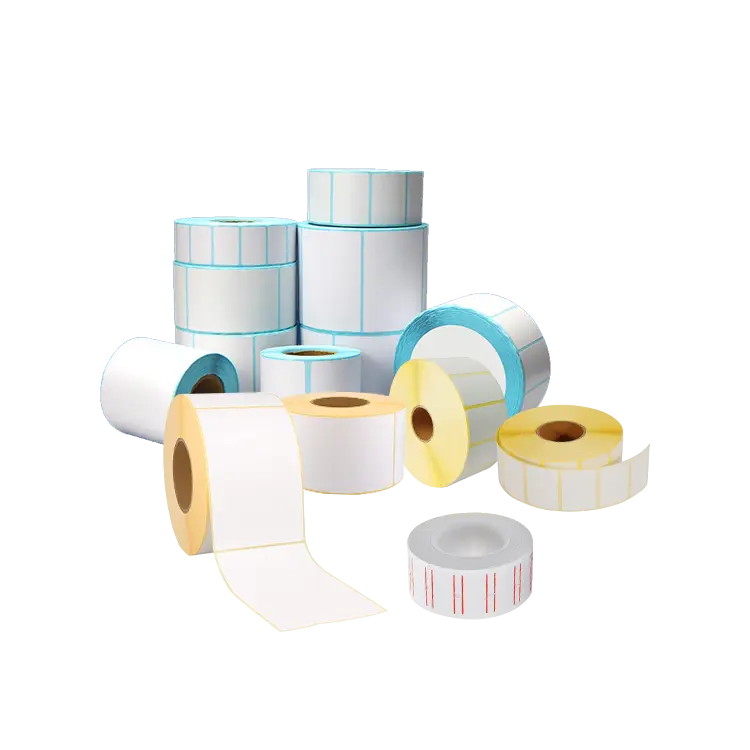

Thermal labels

Thermal labels