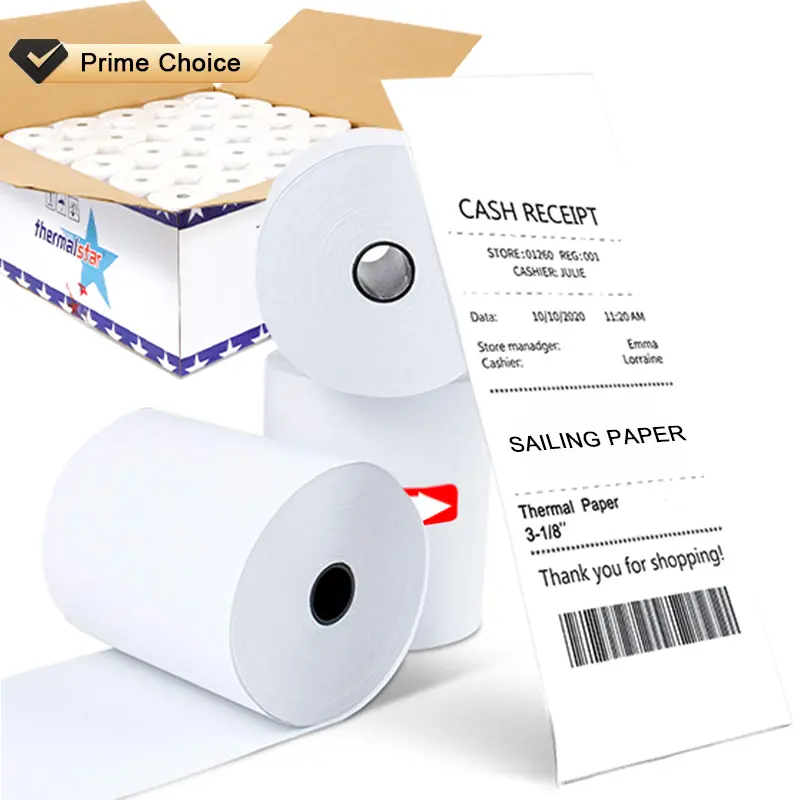

ODM Thermal Paper Manufacturing Process: Get Product Quotes Today

Looking for high-quality thermal paper? Our comprehensive thermal paper manufacturing process ensures top-notch products suitable for various applications. As a leading manufacturer, we focus on creating durable and reliable thermal paper that meets the needs of our clients. You can easily buy our products in bulk, making us an ideal partner for businesses looking to stock up on supplies, We pride ourselves on our commitment to quality and sustainability, using advanced techniques and materials during production. Our experienced team at ShenZhen Sailing Paper Co., Ltd. works closely with you to ensure that the thermal paper you receive is exactly what your business needs, Whether you're a small company or a large corporation, we’ve got you covered. Reach out to us today and discover why we’re one of the top choices for thermal paper in the industry. Don't miss the chance to partner with a reliable company known for excellence!

How To Evaluate Thermal Paper Manufacturing Process Product Factory Dominates

In today's highly competitive market, the manufacturing process of thermal paper plays a vital role in determining product quality and reliability. For global buyers, understanding how to evaluate thermal paper manufacturers is essential for making informed decisions. When exploring potential suppliers, it's crucial to consider factors such as production capacity, technology, and the sustainability of materials used in their processes. Since its inception in 2011, Sailing has evolved from a local paper converter to an international leader in the production and export of printing, packaging, and logistic consumables. With manufacturing bases in China and Malaysia, we leverage advanced technology and stringent quality controls to ensure our thermal paper meets the highest international standards.

Moreover, selecting a factory that prioritizes efficiency and innovation can significantly impact your supply chain. At Sailing, we employ state-of-the-art machinery and adhere to best practices in manufacturing, which enables us to deliver high-quality thermal paper that caters to diverse applications. Our commitment to customer satisfaction and long-term partnerships ensures that our products not only meet but exceed industry expectations. As you evaluate potential suppliers, consider their track record, product range, and responsiveness to customer needs—essential elements that can ultimately influence your business’s success in the global market. By partnering with a reliable manufacturer like Sailing, you gain a competitive edge and a trusted source of high-quality thermal paper.

How To Evaluate Thermal Paper Manufacturing Process Product Factory Dominates

| Process Step | Key Parameters | Efficiency (%) | Waste Generated (kg) | Quality Score (1-10) |

|---|---|---|---|---|

| Raw Material Selection | Quality & Cost | 95 | 50 | 9 |

| Coating Application | Thickness & Uniformity | 90 | 30 | 8 |

| Drying Process | Time & Temperature | 92 | 40 | 9 |

| Finishing Operations | Trimming & Cutting | 88 | 25 | 8 |

| Quality Control | Testing & Inspection | 85 | 20 | 10 |

| Packaging | Material & Design | 93 | 10 | 9 |

Comprehensive Comparison of Thermal Paper Manufacturing Process Product in 2025 Now Trending

J

Jameson Harris

Great value for the quality! The service team was highly skilled and attentive to my needs.

10

June

2025

S

Sebastian Baker

Impressive product quality! The team provided exemplary service with thorough responses.

13

June

2025

S

Sofia Mitchell

Absolutely wonderful quality! Their team demonstrated unparalleled professionalism throughout.

01

July

2025

N

Noah Lewis

Awesome product quality! The support team offered thorough and professional assistance.

11

June

2025

M

Mia Thompson

Incredible quality! The professionalism of their staff during follow-up was impressive.

30

June

2025

G

Grace Hall

Impressive quality! The professionalism of the service team made a positive impact on my experience.

24

May

2025

Thermal labels

Thermal labels