0102030405

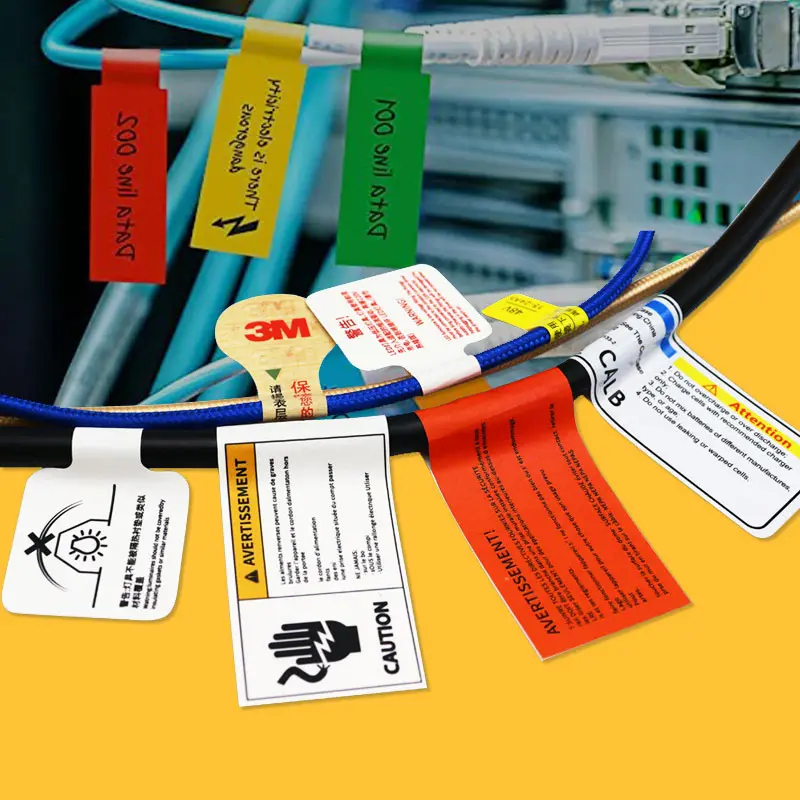

Custom Industrial Labels Heavy Duty Metal Warning Durable Stickers

Short Description:

description2

What are industrial warning labels?

Industrial warning and safety labels are labels used to alert operators or users to potential hazards and are commonly found in manufacturing environments, on equipment, machinery or chemical containers. They usually carry eye-catching icons, text or colours to communicate safety warnings or precautions for use. These labels serve as a reminder to avoid hazards such as electrocution, heat, explosion, corrosion, etc., ensuring workplace safety and operational compliance. Industrial warning labels are particularly common in high-risk environments such as factories, construction sites, and laboratories.

Why is the heavy duty industrial labels important?

Resistant to Extreme Environments: Heavy duty industrial labels are typically designed to withstand harsh conditions such as high and low temperatures, humidity, chemical corrosion, UV exposure and mechanical abrasion. This allows them to maintain their integrity and readability in harsh working environments, ensuring that critical information remains valid for a long time.

Ensure safety: In industrial production, equipment and hazardous materials need to be clearly labelled. industrial self adhesive labels help workers to quickly identify risks and operating practices, reducing the likelihood of accidents and safeguarding the workplace.

Compliance needs: Many industries, such as petrochemical, manufacturing, and construction, are subject to strict regulations that require equipment and tools to be marked with specific information. Heavy-duty industrial self adhesive label meet these regulatory requirements, avoiding legal issues and compliance risks.

Reduced Maintenance Costs: Due to the durability of industrial equipment labels, companies don't need to replace them as often, reducing maintenance and replacement costs while ensuring that equipment information is always available.

How to select the correct heavy duty industrial labels?

Environmental conditions:

Temperature range: Determine the temperature limit to which the label will be exposed and select a label material that can withstand high or low temperatures, such as metal, polyester or vinyl.

Outdoor Exposure: If the custom industrial label is to be used outdoors, make sure it is UV and weather resistant to prevent fading, cracking or damage.

Durability:

Choose a material with strong abrasion resistance to ensure theindustrial metal labels remain legible over long periods of use.

Choose industry labels with an overlay or special protective coating for added protection.

Adhesion:

Surface type: Determine the type of surface to which the label will be applied (e.g., metal, plastic, paint, etc.) and ensure that an adhesive is selected that is suitable for that surface.

Surface roughness: If the industrial sticker labels is to be applied to a rough or irregular surface, choose alabel industrial with strong adhesion to ensure that it is strong and does not come off.

Information durability:

Printing method: The information on the industrial durable labels needs to be preserved for a long period of time, choose a label material that can support durable printing methods such as thermal transfer, laser engraving, etc., to ensure that the text, barcode or 2D code will not fade.

Scratch resistance: Ensure that the industrial label sticker have good scratch resistance to avoid blurring of information due to friction.

Special features:

Tamper resistance: if you need to prevent unauthorised manipulation or disassembly, choose labels with tamper-resistant features such as fragile labels.

What should I pay attention to when pasting heavy duty industrial labels?

Surface Cleanliness: Make sure the surface is clean and dry before applying. Oil, dust, moisture or other impurities can affect the adhesion of the industrial machine labels.

Surface flatness: Industrial roll labels should be pasted on a flat surface. If there are irregularities, roughness or curvature on the surface, it may affect the industrial stickers labels adhesion.

Applying pressure: When applying custom industrial labels, apply enough pressure to press the industrial label stickers evenly so that it makes full contact with the surface. This activates the label's adhesive and ensures a stronger adhesion.

Wait for the adhesive to cure: After applying, the adhesive needs time to cure. Avoid applying pressure to the industrial self adhesive labels or exposing it to harsh environments immediately after applying it; a wait of 24 to 72 hours is usually recommended to ensure the label reaches maximum adhesion.

Surface Material Matching: Select the appropriate custom industrial label based on the material of the surface. Different label materials (e.g., metal, plastic, glass, etc.) have different adhesion properties to custom industrial adhesive labels, ensuring that you select heavy-duty labels and adhesives that are appropriate for that material.

Weathering considerations: If the industrial product labels will be exposed to sunlight, rain, chemicals or other harsh environments for a long period of time, make sure that the selected industrial label stickers have good weathering, UV resistance, and is water and chemical resistant.

Thermal labels

Thermal labels