How to make custom printed thermal paper?

2024-09-25

Nowadays, various marketing methods are emerging, and thermal paper is no exception. With the changes in market demand, thermal printing paper is not only used for traditional receipt and invoice printing, but also has become a powerful tool for brand promotion. By customizing and printing brand logos, promotional information or advertisements on thermal credit card rolls, companies can not only increase brand exposure, but also enhance brand awareness and trust in customers' daily consumption. This innovative marketing method, especially in industries such as retail and catering, can effectively improve marketing results and increase customer stickiness. Next, we will introduce in detail how to make custome pre printed thermal paper, as well as the key steps and factors to consider in the customization process.

Custom thermal paper roll size:

First, we need to know the thermal printer paper size that the customer needs to print. Common sizes are usually:

Of course, the above are just the common size of thermal printer paper that can be customized for printing. Sailing also supports customized sizes and custom printed thermal paper. At the same time, you need to confirm the size of the inner core of the thermal billing paper roll, which is usually 15mm/17mm. Welcome to learn more and inquire.

Design draft:

After understanding the thermal paper roll sizes required by the customer, the most important thing is to understand the product design drawing. First, we need to ask the customer to provide the corresponding design drawing source file, so that we can effectively and accurately understand what the customer wants (such as color). However, if the customer does not have his own design drawing, Sailing now has a very good welfare mechanism for customers. You can tell us your ideas, and we can also design for you free of charge according to your needs.

Determine the printing surface and winding direction of custom printed thermal paper:

We know that thermal till rolls has two sides, one is the thermal coating side, and the other is the non-thermal side. Since we are currently discussing custom printed thermal paper, the non-thermal side is generally the side that needs to be fully customized, while the thermal coating side can be thermally printed (and may also have some customized printed patterns). So at this time we need to determine with the customer how to print, whether the printing surface is only printed on one side or both sides? And which side of our product needs to be wound outwards?

Material selection and printing process:

According to customer needs, select suitable thermal printing papers substrates (such as BPA Free or BPS Free) to ensure that the printing and printing quality meet the requirements. Then use advanced printing equipment to customize the thermal paper. Common printing methods include flexographic printing or UV printing. Generally speaking, simple 1-8 colors use flexographic plates, and complex gradients require UV printing.

Proofing confirmation and mass production:

Before mass production, thermal paper suppliers will provide samples for customer confirmation. The proofing process is a key step to verify whether the design and material selection meet expectations. Customers can actually view and test the proofing products, including: checking whether the printed pattern is clear, the color is saturated, and whether it meets the design requirements; testing the performance of thermal paper rolls in use to ensure that it runs smoothly in the printer, does not cause paper jams, and prints clearly and quickly.

When the customer confirms the sample, the thermal paper supplier will start mass production. The production process involves multiple links, including paper printing, slitting, rolling, etc. The supplier will arrange the production time according to the order volume to ensure that it is completed on time.

Quality inspection and packaging:

After production is completed, the supplier will conduct a quality inspection on each batch of products, with the following key points:

Size consistency: Ensure that the size, weight, inner core diameter, etc. of the paper roll thermal meet customer requirements.

Printing quality: Check whether the printed pattern is consistent with the proof, and whether there are any problems such as missing or wrong printing.

Paper quality: Ensure that the paper surface is not damaged and the paper roll is curled tightly for subsequent use. After passing the inspection, the supplier will package according to customer requirements to ensure that the product is not damaged during transportation.

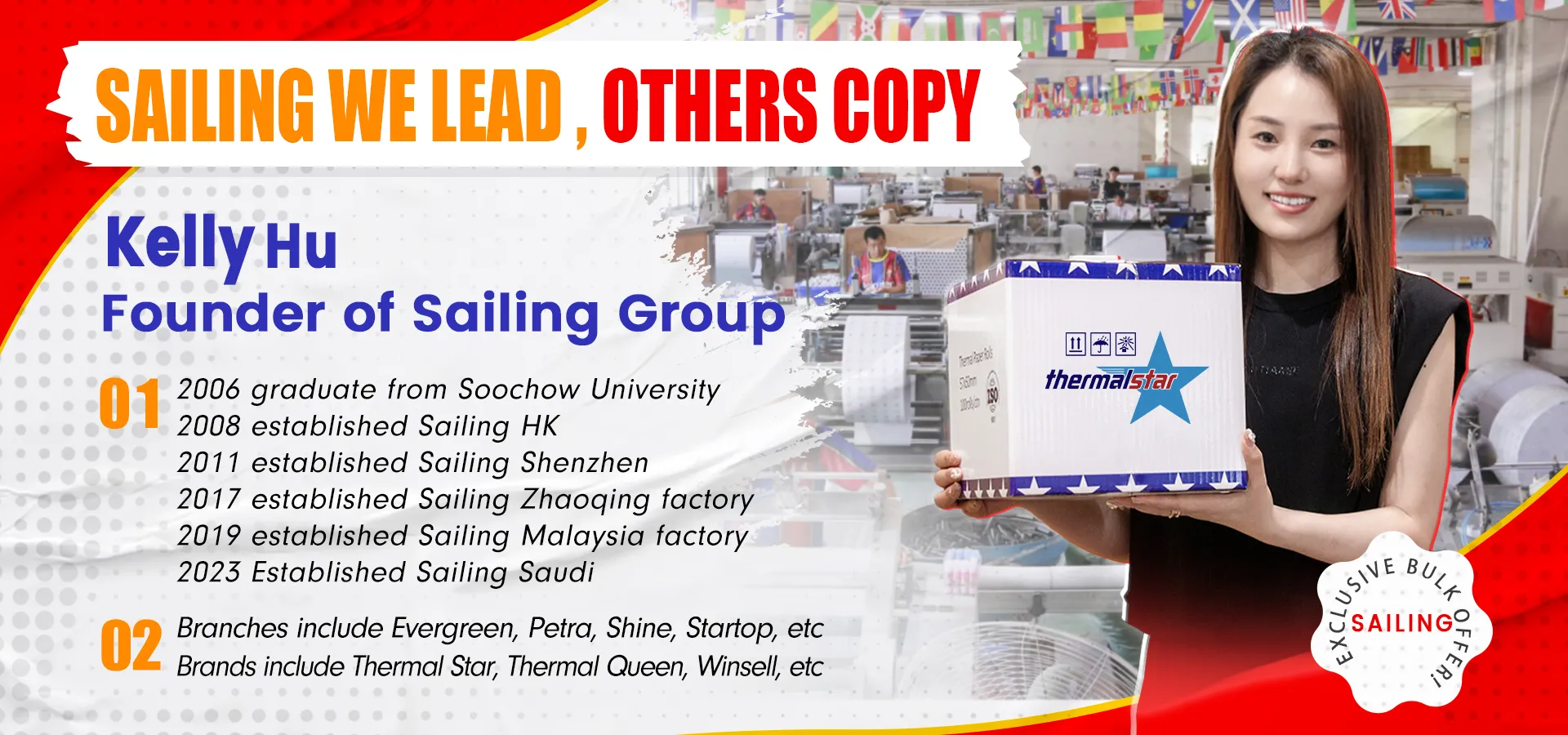

The above is the entire process of making custom printed thermal paper. Through the above steps, customers can custom thermal paper products that meet their specific needs. This process ensures that every link of the product from design, proofing to mass production can be accurately executed, and finally provide high-quality customized thermal paper roll. Sailingpaper has been committed to thermal paper manufacturing for 19 years. With years of industry accumulation, it provides high-quality and customized thermal paper products to meet the diverse needs of customers around the world. Through continuous technological innovation, the company ensures that its products have excellent printing effects and lasting durability. Sailingpaper has always been at the forefront and has become a trusted supplier for many customers! If you currently have a need for custom printed thermal paper rolls, please contact us!

Thermal labels

Thermal labels